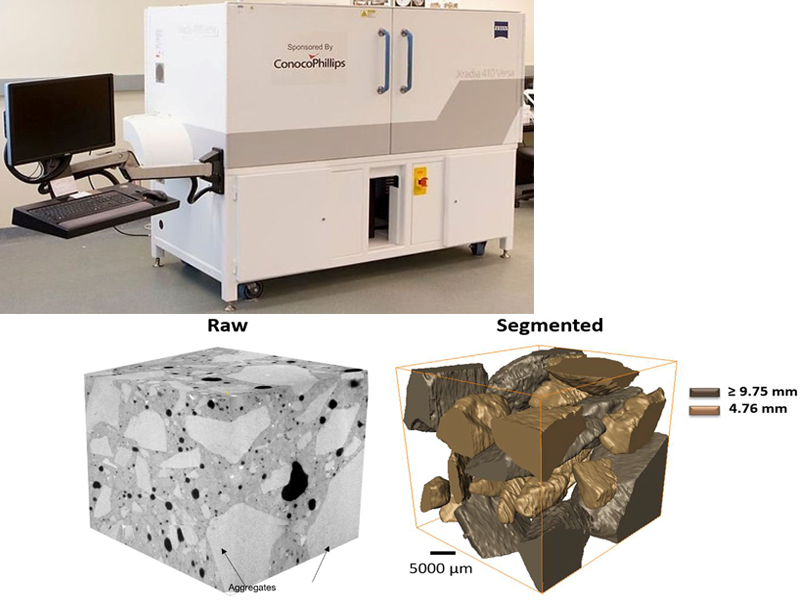

ATRC Imaging Suite Equipment

Zeiss X-ray Computed Tomography

Size and spatial distribution of aggregates in a concrete sample

Sokhansefat, G. et al., Cement and Concrete Composites, 2019, 98, 150-161

Resolution: 100 nm–70 µm/pixel

This instrument can take non-destructive 3D scans of the internal structure of materials. Some of its application include characterizing porosity and micro rock structures, understanding crack propagation in ceramics, metals and building materials. This instrument can achieve a minimum scan pixel size of 100 nm. It has a large chamber for different in-situ testing stages to be constructed such as load, pressure, or adding fluid. This makes it possible to characterize material evolution in 4D (time-based).

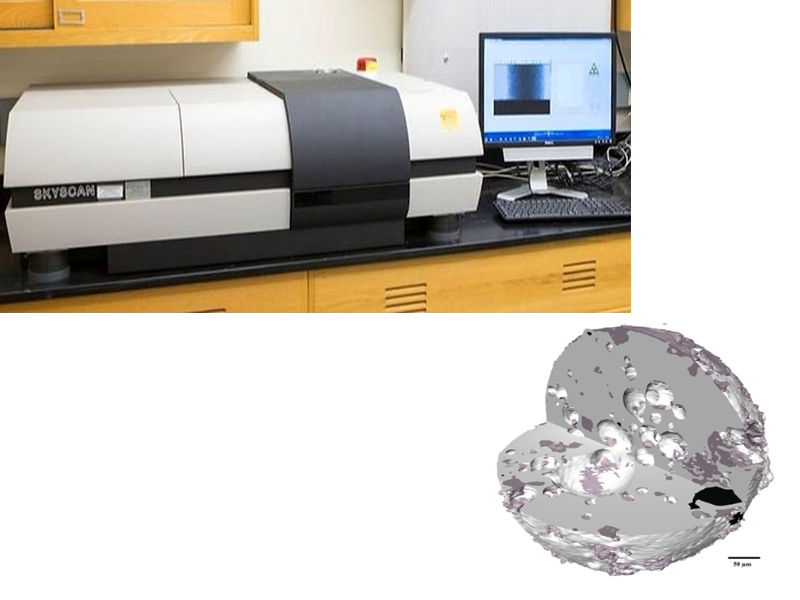

Skyscan 1172 X-ray Computed Tomography (CT)

Resolution: 1–25 µm/pixel

This instrument provides non-destructive elemental analysis with the flexibility to work across a wide range of sample types and shapes. There is minimal sample preparation, and no coating is required. It can detect spot sizes from 2 mm down to 50 micron. It has a large vacuum chamber that accommodates samples up to 270 mm (W) by 270 mm (D) by 100 mm (H).

A 3D model of the segmented micro computed tomography data of a fly ash particle.

Hu et al., Fuel, 2014, 116, 229–236

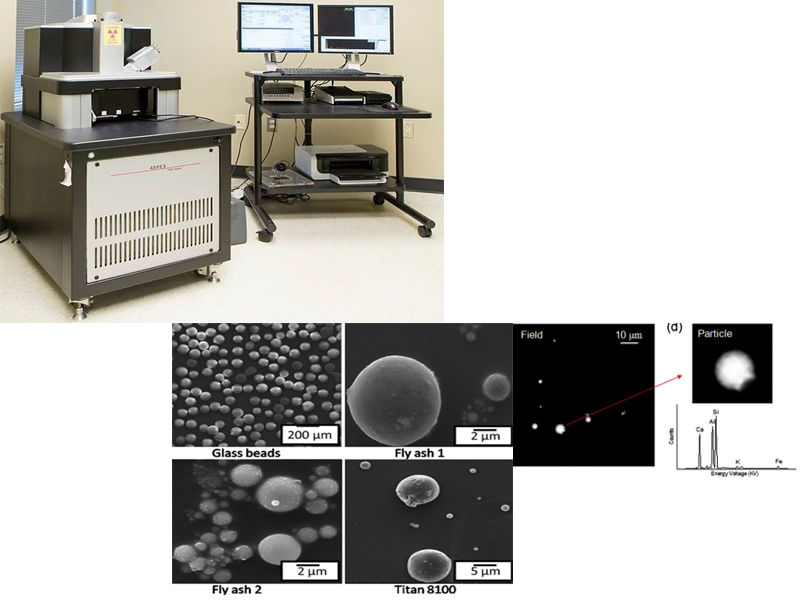

Orbis Micro X-ray Fluorescence Microscope (XRF)

Elemental map of a concrete sample

Moradllo, M. K. et al., Cement and Concrete Research, 2017, 92, 128–141

Resolution: Down to 50 µm/pixel

This instrument provides non-destructive elemental analysis with the flexibility to work across a wide range of sample types and shapes. There is minimal sample preparation, and no coating is required. It can detect spot sizes from 2 mm down to 50 micron. It has a large vacuum chamber that accommodates samples up to 270 mm (W) by 270 mm (D) by 100 mm (H).Aspex Explorer Automated Scanning Electron Microscope (SEM) with Energy Dispersive Spectroscopy (EDS) technology

Magnification: 7x–240,000x

This SEM is designed for the automated imaging and elemental analysis of surfaces and particulate. It can be trained to find different areas of interest and investigate them without human intervention. The system is optimized for sizing and measuring the elemental composition of particles from 0.5 micron to over 100 micron. It is capable of scanning ~10,000 particles per hour when collecting both size and compositional data or ~30,000 particles per hour without EDS when collecting only sizing data.

This SEM is designed for the automated imaging and elemental analysis of surfaces and particulate. It can be trained to find different areas of interest and investigate them without human intervention. The system is optimized for sizing and measuring the elemental composition of particles from 0.5 micron to over 100 micron. It is capable of scanning ~10,000 particles per hour when collecting both size and compositional data or ~30,000 particles per hour without EDS when collecting only sizing data.

Aichele et al., Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2015, 479, 46– 51.

Aboustait, M. et al., Construction and Building Materials, 2016, 106, 1–10