AICHELE RESEARCH GROUP

Oldershaw Column and VLE

Oldershaw Column

Although distillation is one of the most well-developed separation technologies, distillation efficiency prediction is an area that needs more research to develop better efficiency correlations. Doing pilot-scale testing to develop better distillation efficiency correlations can be expensive. Lab-scale Oldershaw distillation columns are proven to be effective in representing the point efficiency of commercial columns. Therefore, they can be of substantial use in giving invaluable information to develop better efficiency correlations and to design distillation columns for complex systems such as systems with high viscosities.

We started a project in 2016 (funded by Fractionation Research Inc.) to investigate the effect of liquid viscosity on point efficiency of distillation trays. We commissioned an Oldershaw experimental facility at OSU with the following characteristics.

-

Our current setup can be operated at deep vacuums down to 0.02 bara.

-

We have a high precision vacuum controller to control the vacuum at the top of the condenser.

-

The temperatures are accurately measured with 4 wire RTDs.

-

Capable of collecting samples at deep vacuum without disrupting steady state operation.

-

The column components are well insulated with vacuum jackets and silver coating.

-

The trays are 2 inches in ID and have sieve holes with 10% tray open area.

-

The setup is modular with the ability to change the number of trays.

-

Equipped with Martin Monsanto liquid dividing head for automatic control of reflux ratio.

-

The entire setup is shielded for safe operation at deep vacuum and atmospheric pressure conditions.

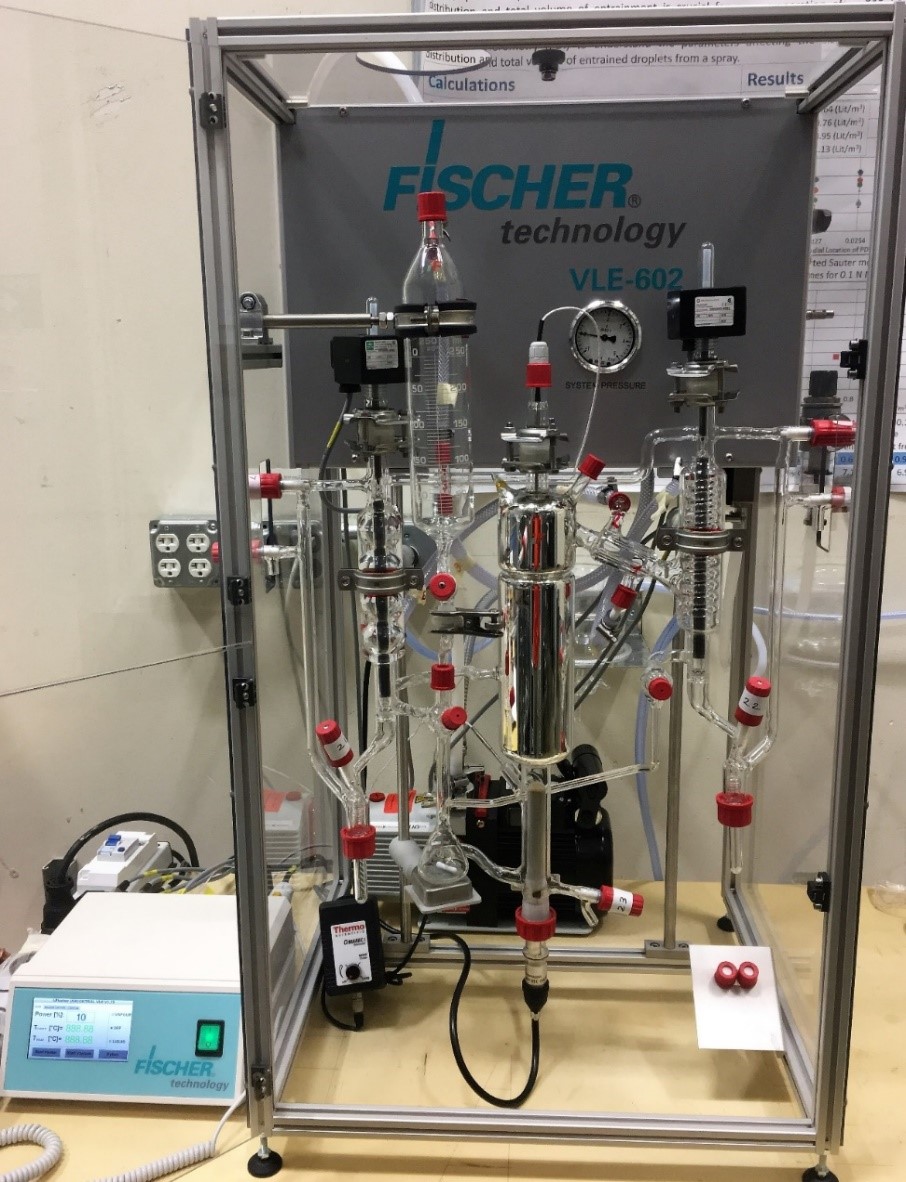

VLE Apparatus: FISCHER® LABODEST® VLE 602

-

Our current setup can be operated from 0.01 bara to 1.05 bara.

-

We have a high precision vacuum controller with ±1 mbar accuracy to control the vacuum at the top of apparatus.

-

The temperatures are accurately measured (±0.1 K) with the resolution of 0.01 K.

-

Equipped with special devices for sample collection at deep vacuum without disrupting the steady state.

-

The separator is well insulated with a vacuum jacket and silver coating.

-

The setup is modular with the ability to modify it for operations from 0 to 4 bara.

-

The entire setup is shielded for safe operation.