Civil & Environmental Engineering

Concrete Materials

Both concrete materials and concrete construction work have been focal points in CIVE at Oklahoma State University. The research team at OSU have focused on solving real-world problems through using real equipment. OSU has both a concrete paver and a concrete pump. They also have a temperature-controlled mixing, curing, and nine environmentally controlled chambers where they can simulate different weather conditions.

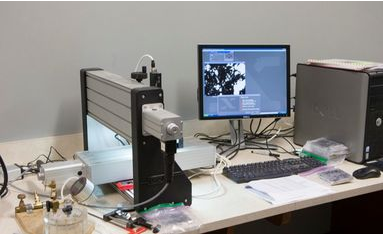

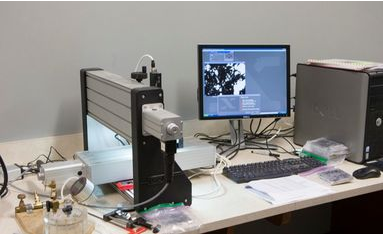

Further, concrete mixing can be completed in a temperature and dust controlled mixing room at the BCEL. Some of the fresh properties testing for concrete include: Slump, temperature, Unit Weight, Type B air meter, six super air meters, and the Box Test. Isothermal calorimetry testing can also be measured. Multiple hydraulic presses can be used for compressive, tension, and flexural testing. Most concrete durability testing can be completed such as hardened air void analysis, bulk freeze-thaw, alkali silica reaction, sulfate attack, and carbonation. For example, with freeze-thaw durability, Figure 2 (a) through (d) show the sample preparation process from cut with a concrete saw, polished on multiple automated polishers, coloring prepared with a stereomicroscope, and scanned with an automated hardened air-void analysis (Rapid Air 457). Also, bulk freeze-thaw testing can be completed using one of the five freeze-thaw chambers (see Figure 2e). In addition, physical and chemical testing of cement, fly ash, and slag can also be conducted.

Concrete MaterialsAnd Equipment

-

Aggregate

Most of the typical aggregate testing can be completed such as gradation, LA abrasion, potential ASR reactivity, freeze-thaw durability, flat and elongation, absorption, specific gravity, voids content, and unit weight. The BCEL has a designated aggregate room for sieving and LA abrasion. Chemical testing can also be conducted on the aggregate. The OSU CIVE research team also has the abilities to test aggregates for mechanical responses such as California Bearing Ratio (CBR), Triaxial Shear Strength, Resilient Modulus (MR) and Permanent Deformation Accumulation under Repeated loading. The team can test cylindrical triaxial specimens with a diameter of 152 mm (6 in.) and a height of 305 mm (12 in.). These triaxial tests can be conducted with complete pore-water pressure control. Moreover, the set-up can also measure the permeability during the triaxial testing.

-

Numerical Modeling Capabilities

The OSU CIVE team has expertise in the use of several state-of-the art numerical modeling software packages. Some of the most commonly used software packages include:

- ABAQUS for Finite Element Modeling of structures, embankments, pavements, and railroad tracks

- Particle Flow Code (PFC) for Discrete Element (DE) Modeling of coarse-grained geomaterial behavior. Example applications include: (a) interaction between aggregates and geogrids in pavement and railroad applications; (2) studying the mechanism of particle breakage under repeated loading, etc.;

- Fast Lagrangian Analysis of Continua (FLAC; both 2D and 3D versions) for geotechnical analysis of soils, rocks, groundwater, and construction processes such as excavation.

-

Nondestructive Testing

For many construction materials there has been extensive nondestructive testing capabilities for both laboratory and field application. This nondestructive testing can be found in many forms throughout the laboratory depending on the research project. While NDT strength testing capabilities of rebound test, penetration test, pull-out test, and break-off test can be found in many material laboratories, the BCEL also has ultrasonic pulse velocity devices with 54 kHz and 150 kHz P-wave transducers and 250 kHz S-wave transducers to enable estimation of dynamic modulus of elasticity of materials. These ultrasonic pulse velocity devices have been used to not only determine the uniformity of a concrete structure, but monitor the crack development with a concrete sample being loaded. The BCEL also has the ability to complete acoustic emission testing. This is where high resolution microphones are used to detect cracks within materials as they occur.