Research Projects

-

Mechanochemistry at the Nanoscale

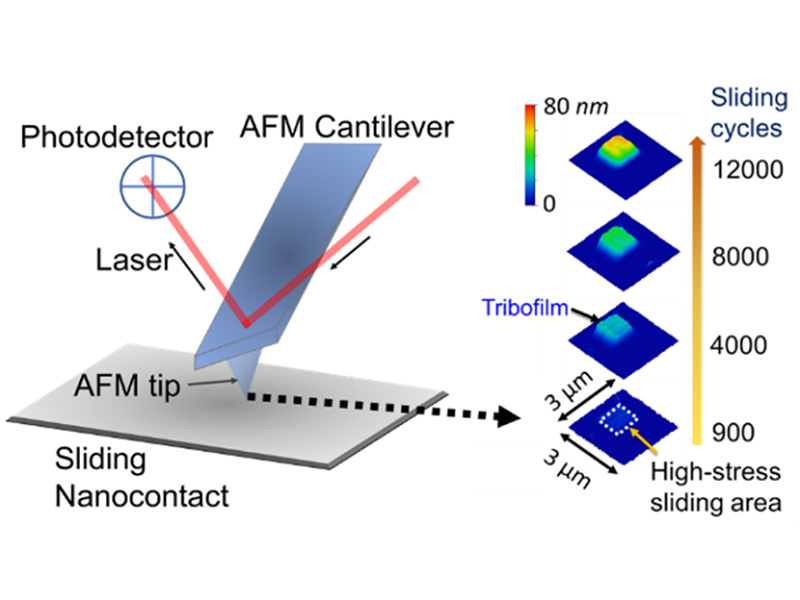

Mechanochemistry uses mechanical forces to drive chemical reactions. Using in-situ scanning probe and optical techniques, we develop a mechanistic understanding of how local stress states influence reactivity at sliding contacts. We apply these insights to design stimuli-responsive materials; for example, materials that counteract friction and wear by forming lubricious, protective tribofilms through mechanochemical reactions. We are currently studying mechanochemical reactions catalyzed by high entropy alloys.

Researcher: Bunty Tomar

Collaborator: Prof. Ritesh Sachan (OSU)

Atomic force microscope as a stress-controlled nanoreactor to study mechanochemistry at sliding contacts

-

Tribosintering

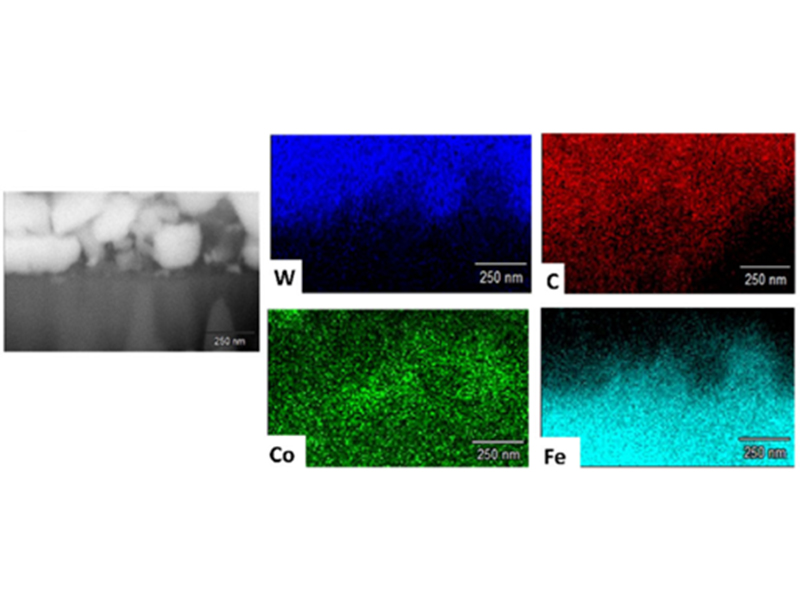

We study how nanoparticle sinter under concentrated stresses at sliding interfaces in a process known as tribosintering. In our recent Nano Letters publication, we showed that combining contact stresses with electric fields enables refractory nanocomposite films to sinter at remarkably low temperatures (around 100 °C) within minutes. Ongoing projects are probing the nanoscale structure and properties of tribosintered films.

Researchers: Bunty Tomar, Foyez Ahmad, Zidan Mohiuddin

Cross-section micrographs showing a WC-Co film sintered on a steel substrate via electric field-assisted tribosintering (Nano Letters 2025)

-

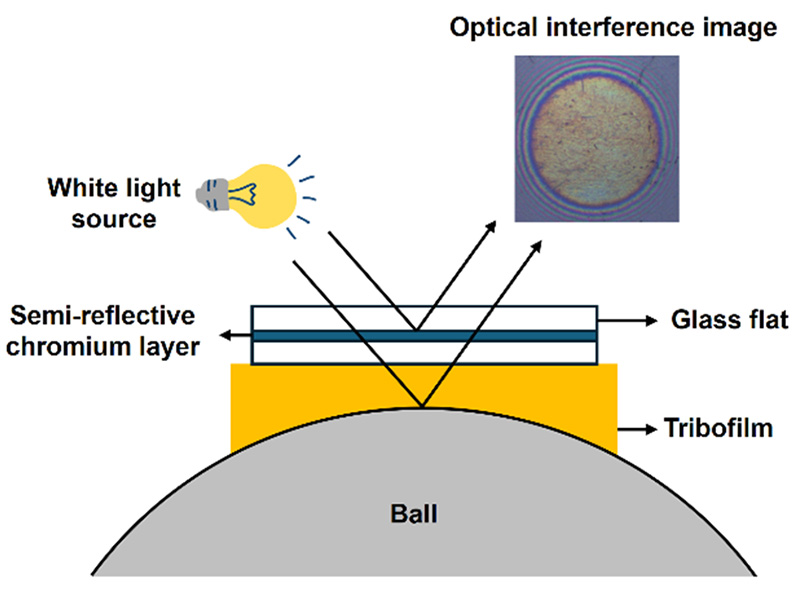

Tribology under Electric Fields

We study the fundamental mechanisms of friction, wear, and lubrication under electric fields. This knowledge guides the development of advanced materials and lubricants for electric vehicles, electric aircraft, and power generation systems.

Researcher: Foyez Ahmad

Collaborators: Dr. Jun Qu (Oak Ridge National Laboratory), Prof. Kaan Kalkan (OSU), Prof. Dave McIlroy (OSU)

In-situ optical interferometry to probe lubrication mechanisms at sliding interfaces

-

Cold Spray Additive Manufacturing

The cold spray process exploits impact bonding and high strain rate plastic deformation to 3D print metals, starting with tiny microparticles as building blocks. Our group is developing new strategies to enhance bonding in cold sprayed materials.

Researcher: Chandler Saxon, Bunty Tomar, Hayden Dailey