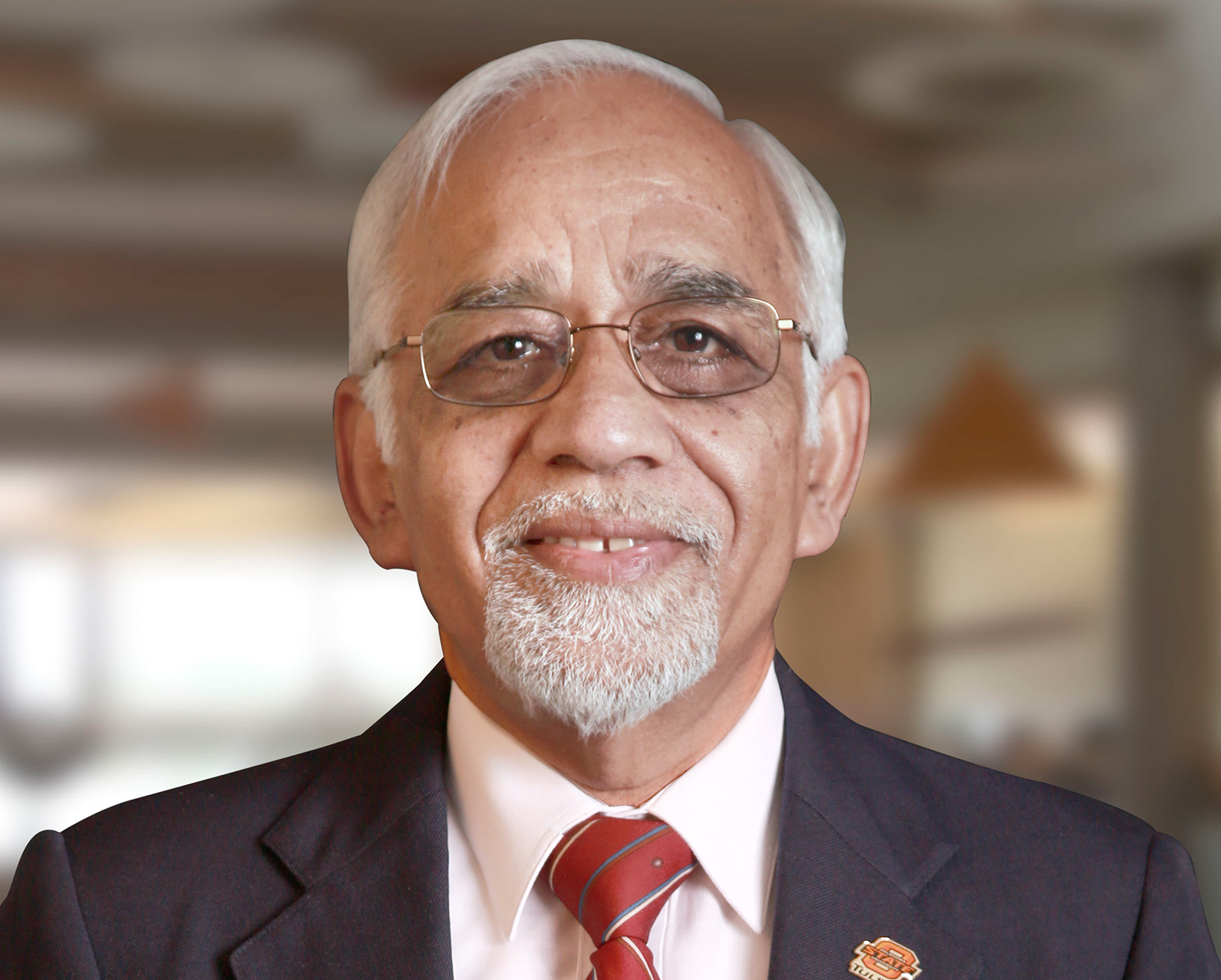

Dr. Raj N. Singh, Sc.D.

Academic Background

Sc.D.

Ceramics

Massachusetts Institute of Technology, Cambridge, MA

M.S.

Physical Metallurgy

University of Manitoba, Winnipeg, Canada

B.S.

Metallurgical Engineering

Indian Institute of Technology, Kanpur, India

Areas of Interest

- Nanostructured Materials

- Energy Storage Materials

- Biomaterials

- Thermal Management

- Fuel Cells

- Composites

- Electrical Ceramics

- Materials for Quantum Systems

Courses Taught

- ENSC 3313, Materials Science

- MSE 5033, Composite Materials

- MSE 5053, Smart Materials

- MSE 5103, Electrical and Optical Properties of Ceramics

- MSE 5143, Batteries and Supercapacitors for Energy Storage

- MSE 5093 Fundamentals of Material Science

- MSE 5193 Advanced Materials Processing

About

Dr. Singh received his Sc.D. degree in Materials Science and Engineering-Ceramics from M.I.T. He is a member of the National Academy of Engineering (NAE), a Fellow of the National Academy of Inventors (NAI), a Fellow of the American Association for the Advancement of Science (AAAS), a Fellow of the American Ceramic Society, a Fellow of the ASM International, and a Fellow of the Graduate School at University of Cincinnati (UC), recipient of numerous awards, and author or co-author of over 350 research articles, 28 granted patents, and articles in several books. He has worked at several R&D organizations such as Argonne National Laboratory, GE R&D Center and University of Cincinnati before joining his present position. He has also served as Department Head of Materials Science and Engineering and Department of Chemical and Materials Engineering at UC.

His current research areas are processing and properties of materials for quantum devices, materials for thermal management of electronic devices, nanostructured materials and nanotubes/nanorods, materials for fuel cells, batteries, supercapacitors, nanomaterials for medicine, "Smart"/ferroelectric materials, structural ceramic matrix composites, and novel thin films. He is recognized for scientific and technological contributions to ceramic matrix composites, diamond thin films, BNNT, electrolyte retainer for molten carbonate fuel cells (MCFC), electrolyte for Na-S battery, self-healing glass seals and electrolyte and electrodes for solid oxide fuel cells (SOFC) and ferroelectric materials with large (0.8%) strain capability. Dr. Singh pioneered and developed a novel process of melt infiltration (MI) for fabricating fully dense and net-shape SiC fiber-reinforced ceramic matrix composites (CMCs). Gas turbine engine manufacturers and users such as GE, UTC, RollsRoyce, NASA and USAF in the USA as well as worldwide companies in Europe and Japan are pursuing this technology. The MI-CMC products are being used as vanes, blades shrouds and liners in hot sections of turbine engines. GE-Aviation has started several new businesses for manufacturing MI-CMC parts for use in current and future gas turbines with projected market well over tens of billions of dollars for aircraft gas turbines alone. GE Aviation has used these CMCs for the GE LEAP engine for Boeing 737, AirBus A320Neo and COMAC aircrafts since 2016 and GE9x engines for the new Boeing 777 starting in 2019-2020. These are the world’s first jet engines with MI-ceramic composites used as structural turbine components because of the pioneering work of Dr. Singh.